Adjustable Kiosk 2015

Many informal kiosks in the suburbs of African cities are made of everyday materials and recycled waste and are manufactured by local people. Each kiosk has a specific character and responds to a specific need. In this one-week joint workshop, Ugandan and Japanese students were asked to design a kiosk for local vendors. The students started by observing and analyzing existing kiosk designs and were able to identify important characteristics such as the structures’ lightweight, mobility, and the use of self-supporting structure. By the end of the process, the students produced a single design which they named the “adjustable kiosk”. The workshop took place in Nansana, a town on the outskirts of the city of Kampala and the production was carried out in and around the engineering campus of Makerere University, located at the center of Kampala.

Observations

Based on location, two types of informal kiosks were observed: the first type were small kiosks that existed along the main roads and occupied small areas. The designs were composed of self-supporting structures that were lightweight and mobile.The second type was found in the back streets and consisted of relatively larger structures that were assembled under existing trees or the shade of existing house eaves. Additionally, students found that the form, material, color, scale, and adjustability of the kiosks was driven by the merchandise sold on them. During the observation phase photographs and sketches were used. Afterwards, each student was asked to produce detailed/ analytical drawings and share them with other students.

(Local kiosk) Drawing by Yuka Minatozaki

Construction

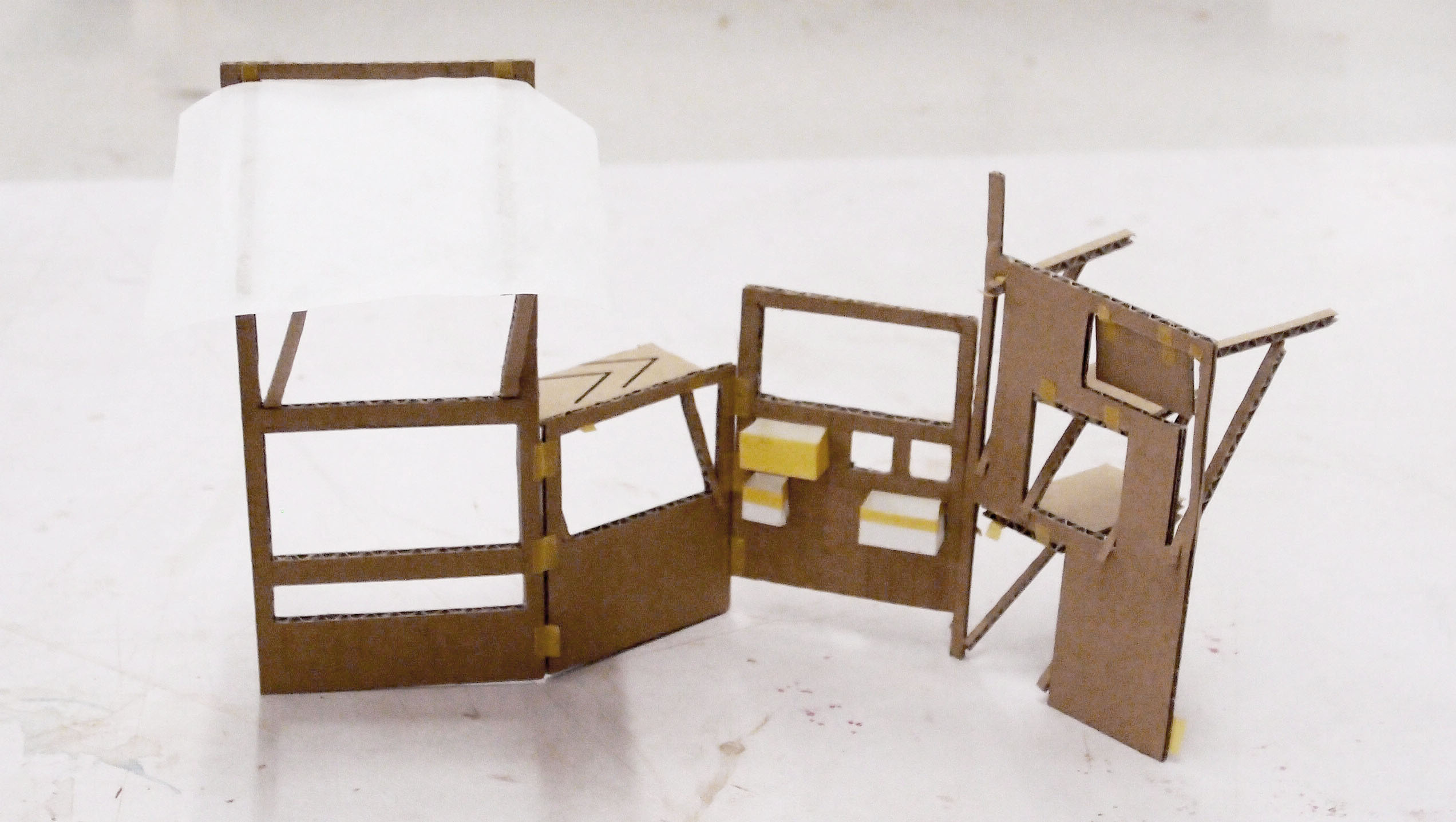

During the construction phase, studentsfaced challenges that were unique to Kampala requiring them to make adjustments to the kiosk’s design. Primarily, differences in material types and hardware sizes as well as limited supplies of certain parts made it difficult to complete segments of the original design. As a result, the students purchased a 9mm ply-board for the main body and used it asa full-scale study. The details of each part of the

design were determined by the size, weight, strength, and accuracy of the main structure. The fabrication process required an efficient and flexible division of tasks and discussions were held as needed.Students were always encouraged to improvise and find alternative solutions when faced with problems. The primary production base was the courtyard of the campus of the Faculty of Engineering where the main part of the assembly process took place.

Adjustability = Transformability

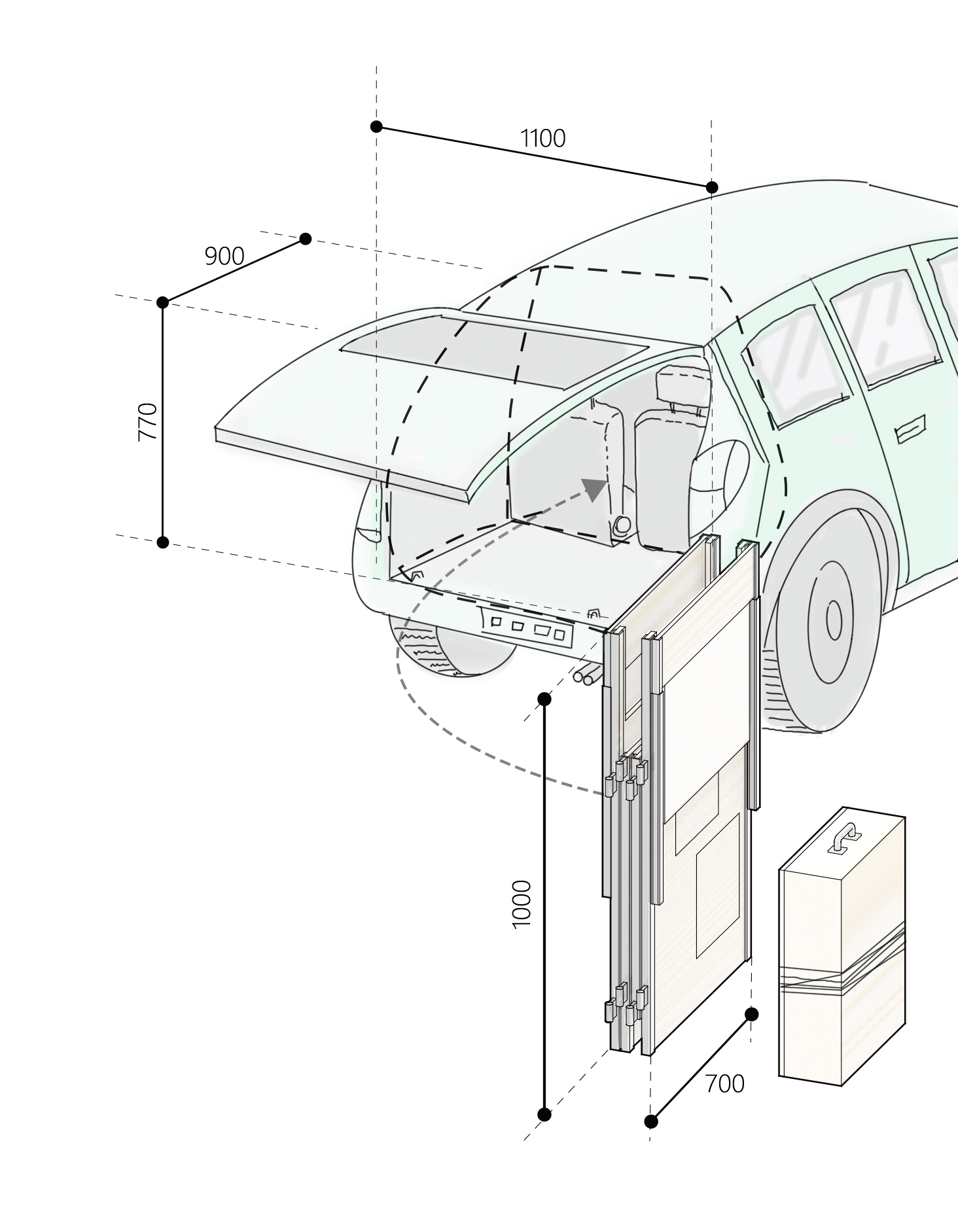

design were determined by the size, weight, strength, and accuracy of the main structure. The fabrication process required an efficient and flexible divisionof tasks anddiscussions were held as needed.Students were always encouraged to improvise and find alternative solutions when faced with problems. The primary production base was the courtyard of the campus of the Faculty of Engineering where the main part of the assembly process tookplace.4-Adjustability = TransformabilityTo achieve ‘Adjustability’, students had to consider multiple variables and situations. When thinking about transportation and due to budget, time, and safety concerns, the kiosk was designed so it could be easily transported by car. To ensure the kiosk remained lightweight, auxiliary structures were designed to provide support on site and protect goods from wind, rain, and theft. There was also a special mechanism that allowed parts of the kiosk to be opened or closed depending on the location and was mainly used to attract customers from various directions. Most importantly, the structure was ‘mobile’ and light enough to be carried by a single individual in case of a raid by the authorities, something that was very common and targeted informal structures along major roads. All of the aforementioned features made this kiosk extremely transformative; it can be compressed, folded, unfolded, and is accessible from different angles. This transformative nature extended to the site as well; the structure is highly customizable and could be used in open spaces as well as narrow spaces surrounded by buildings.

Drawing by Rai Gen

Support:The Japan Institute of Architects

Photo:TERRAIN architects

Participants:Akiko Ono, Tetsuya Saito, Yuka Minatozaki/ Tokyo Univesity of the Arts

Ibingira Gerchom Ireeta, Kamoga Ronald, Esunu Charity Aipikor, Frank Ludovic Sentamu/Makerere University